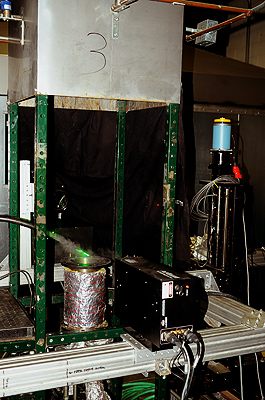

The CFRL has 3 vertical combustion facilities - small scale combustion facilities that can be used for combustion tests on small hardware as well as non-reacting aerodynamics or spray tests. The vertical combustion facilities are equipped with 36 kW inline air heaters. Test hardware can be installed on an ANSI 4” 150 lb standard pipe flange. A 3-D, computer-controlled traverse is available for installing diagnostic equipment. The rigs are connected to the central exhaust systems available in the lab. A health monitoring system, programmed in LabVIEW, monitors the temperatures upstream of the hardware as well as in the exhaust duct. The health monitoring system provides options of emergency shut-off of the air heater and the fuel flow. Additionally, water nozzles are installed on the exhaust duct, to cool down the exhaust gases. The water nozzles are also controlled by the health monitoring system.

The vertical combustion facility has been used for single nozzle combustion studies as well as swirler characterization studies. The 3-D traverse enables installation of diagnostic techniques like PDI, PIV, and LDV, as well as a sampling probe for emission measurement. Tests conducted in the vertical combustion facility are limited by the size of the connecting flange, the capacity of the inline air-heater, and the capacity of the exhaust system |

|