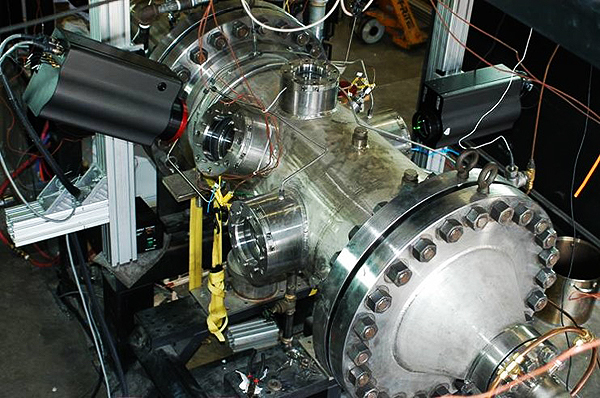

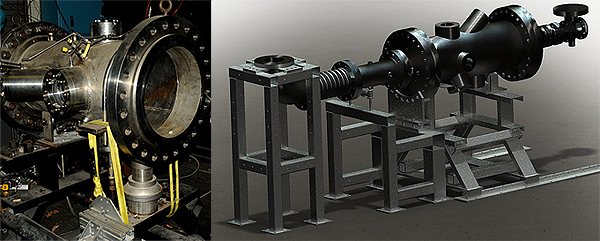

| The high pressure combustion facility can be used to conduct combustion or non-reacting tests at elevated pressure, at room or elevated temperature. A backpressure valve, located downstream of the combustor, is used to increase pressure in the high pressure chamber. A 192 kW inline air heater is available to preheat the air. The outer shell of the high pressure chamber is designed to withstand a pressure of 150 psig and up to 600°F. The air flow passing through the high pressure chamber is divided into two flow circuits. The main air passes through the inline air heater, and flows through a inner flow passage, constituting the burner and a water-cooled exhaust. The second flow circuit enters the region of the high pressure combustor between the inner flow path and the outer shell, forming a cooling layer, protecting the outer shell from the hot flow. 6 windows are located on the shell for optical access. A 3-D traverse is available for installing diagnostic tools.

The high pressure combustion facility has been used for various combustion tests, including nozzles designed for different fuels, as well as liquid jets in crossflow at elevated pressures.

Facility Features

- Static Pressure: 150 psig

- Air Flow Rate: 2 lb/sec

- Air Heater: 192 kW

- Temperature: 800°F

- Inner Diameter: 16.8”

- Traverse control: 3D, fully-automated

- Multi-channel DAQ

- Real-time monitoring and control

- 6-way optical windows

- Diagnostics: High-speed PIV, high-speed PLIF, PDPA, LDA, emission measurements

|

|