|

|

High Pressure Thermoacoustic Rig

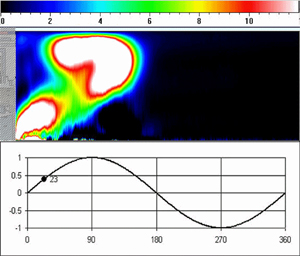

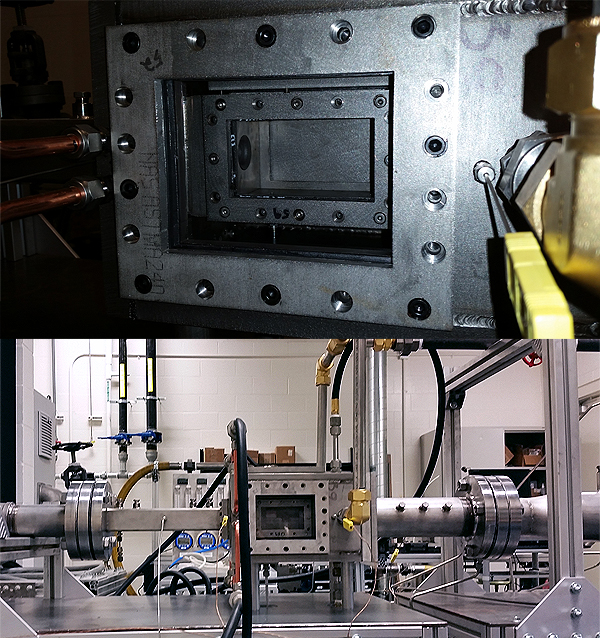

The thermoacoustic gas turbine combustion test rig is designed to diagnose and understand the sources and consequences of combustion instabilities related to unsteady heat release and pressure oscillations. The instability can be induced through the use of an air modulation “siren” or naturally by changing the length of the combustor. Piezoelectric pressure transducers are used to gather data on pressure oscillations and air velocity fluctuations. These can then be related to flame data (high-speed images, high-speed camera spectroscopy, three-line pyrometry, flame spectroscopy, chemiluminescence) or spray data (high-speed Mie-scattering images, PIV). All of this data is then used to develop and evaluate thermo-acoustic network models of the combustor.Capability

The rig is designed to handle pressures up to 5 atm, air flows of up to 0.5 lb/sec, and inlet temperatures of 900°F. The air siren is capable of modulating inlet air flow up to 500 Hz. The combustor is 2.5” x 2.5” and has a variable length.

|

|

|